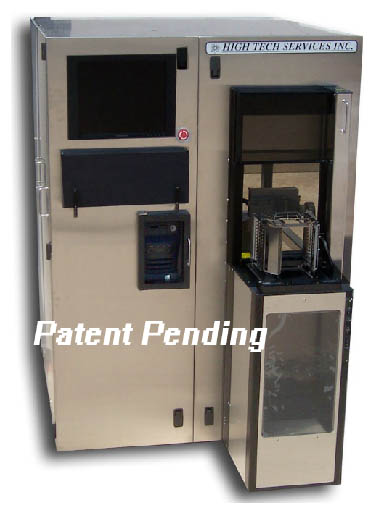

The HTS 9100 Vapor Deposition System was developed for MEMS manufacturers that use Wafer Level Packaging. This system incorporates a single process chamber that will accept a cassette of 24, 200mm substrates in a single process run. By incorporating a SMIF-pod cassette loader the substrates are protected from contaminates in the environment.

System Features

Single chamber

Single vapor source

Recovery trap

Fully automated process control

Manual or automatic loading of cassette.

Single chamber

Single vapor source

Recovery trap

Fully automated process control

Manual or automatic loading of cassette.

Source Features

Capacity - 750 Grams

Maximum temperature - 160 C

Temperature stability during delivery +/- .2C

Controlled vapor saturation

Operating pressure range - 1 to 760 torr

Vacuum bypass for source conditioning

Delivery rate - .2 Grams/min

Capacity - 750 Grams

Maximum temperature - 160 C

Temperature stability during delivery +/- .2C

Controlled vapor saturation

Operating pressure range - 1 to 760 torr

Vacuum bypass for source conditioning

Delivery rate - .2 Grams/min

Process Control Features

Recipe editor

Slow/fast vent

Full data logging

Maximum temperature 150 C +/- .1C

Infinitely variable pumping speed

Variable vapor delivery

Pre/post process purge and pump cycles

Communications/remote access

PID loop temperature controls

Recipe editor

Slow/fast vent

Full data logging

Maximum temperature 150 C +/- .1C

Infinitely variable pumping speed

Variable vapor delivery

Pre/post process purge and pump cycles

Communications/remote access

PID loop temperature controls