High Tech Services offer Vacuum Outgassing Service for vacuum bake out and cleanup of: Connectors, Harnesses, Feedthru, Assemblies and Components.

A typical outgassing process would entail the following:

After receipt and inspection, the component would be documented. At this time, an optional pre-bake (up to 500F) would be performed to reduce the vacuum oven gas load and schedule.

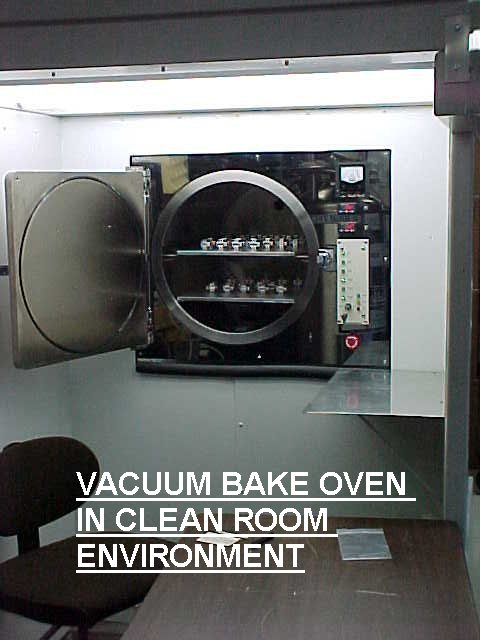

The article would then be placed in the vacuum oven, or in the case of feedthru/harness it would then be "fed through" the oven end plate.

The oven would then be preheated to the specified bake temperature while monitoring thermocouple set points for hot spots. The oven would be vented to atmosphere during this procedure.

Upon reaching temperature, the mechanical cycle would be initiated. Roughing proceeds until a maximum vacuum level of 100u is reached.

At 100u, valve sequencing would expose the heated oven to the high vacuum pump. Pumping continues until either the target vacuum level is attained for the specified time (eg. 10 Torr for 72 hours.) or the desired atmosphere in the chamber, as determined by the RGA is achieved.

The chamber would then be back filled with dry N2 and upon cool down the product would be packaged in antistatic, heat sealed bags with optional desiccant.

The entire process is data logged and a record can be provided with each component.