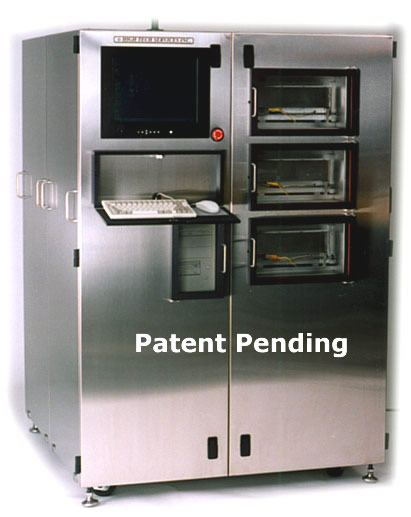

HTS 8100

Vapor Deposition System

The HTS 8100 Vapor Deposition System is the first high throughput production system for applying lubricating films to the surfaces of MEMS devices. These coatings reduce surface tension and eliminate STICTION of micro mechanical surfaces. The HTS 8100 has the capacity to process up to 24, 300mm substrates per hour.

The HTS 8100 three chamber design allows users to deposit on up to three different products at the same time. The software recipe editor allows the user to define all of the process variables for a multitude of processes and products. These two features combined enables the user to develop new processes and products in the same system that they are running production. The dual source feature eliminates maintenance down time and allows production to continue during source recharging and conditioning.

System Features

Three fully Integrated Process Chambers

Two Vapor Sources

Recovery trap

Fully Automated process control

Manual or Auto loading of substrates

Source Features

Capacity - 750 Grams

Maximum Temperature - 160 C

Temperature stability during delivery +/- .2 C

Controlled Vapor Saturation

Operating pressure range - 1 Torr to 760 torr

Vacuum Bypass for source conditioning

Delivery Rate - .2 Grams/Min

Chamber Features

Substrate capacity - 300mm X 300mm X 38mm

Maximum temperature - 150 C +/- .1 C

Temp uniformity +/- .01 C

Base pressure - <10-6 Torr

Dual Vapor Injectors for high deposition uniformity

Infinitely variable pumping speed

Variable Vapor delivery speed

Variable/Ramp N2 vent

Process control features

Recipe Editor

Variable pumping speed

Variable delivery rate

Slow/Fast vent

Pre/Post Process Purge and pump cycles

Full data logging

Communications/Remote Access

PID loop temperature controls

Trap Features

Maximum Capacity - 750 Grams

Running capture rate - 100% up to 100 grams

Regeneration Time - 20 Minutes